Ever find yourself thinking, “How are toilets made?” According to recent surveys, the average person spends roughly 416 days of their life in the bathroom! That’s a lot of time around the porcelain throne!

These fixtures have been a staple in homes across the world since 1596. Yet, few know how commodes come to be.

The truth is, every manufacturer has its own production process. Not only that, but toilet design has evolved significantly over the centuries. To answer this question, we’re going to take a look at the core components and materials that make toilets what they are today.

In This Article We'll Discuss

What Are Toilets Made of?

The most important aspect of the toilet manufacturing process is materials! Back in the early days, you could see toilets wrapped in ornately carved wood. Luckily, we’ve moved on to something a bit more sanitary.

The most common material for toilets these days is porcelain. Porcelain is a type of ceramic material that’s often used in pots and dishwater. Many people refer to it as a raw material. In reality, porcelain is a mixture of ingredients.

These include kaolin, silicate minerals, and powdered feldspar. Some manufacturers may also include some additional ingredients to create a proprietary mix. Either way, those ingredients combine to create a thick clay-like slurry!

Porcelain is the go-to material for many reasons. It all boils down to the material’s resilience. When produced correctly, it’s smooth and easy to clean. Thus, it’s more sanitary! That said, porcelain is almost impervious to water penetration.

To make it fully waterproof, manufacturers take advantage of a treatment called vitreous china. You might see modern toilets labeled as “vitreous china” rather than ceramic or porcelain. It’s not actually the material. Rather, it’s the coating.

Vitreous china is an enamel coating that gives toilets that glass-like finish we know. It makes the porcelain smooth and non-porous for easy cleaning.

Why Are Toilets Porcelain?

There are other materials available for production. Composting and portable toilets are made of plastic. So why not use it for residential commodes?

Plastic is expensive to produce. The extrusion process would require a significant amount of plastic. Even then, it could never achieve the strength of porcelain.

Plus, plastic degrades over time. Eventually, the moisture and waste in the toilet would leach into the plastic and vice versa. This would make your commode unsanitary.

Steel is another option. Steel appliances and food preparation surfaces exist. So why don’t manufacturers use it for toilets? You can find steel toilets in prisons and airplanes.

However, it’s not a favorite for residential toilets because of weight and thermal heat transfer. The material gets cold quickly, resulting in an unpleasant user experience.

The Manufacturing

The manufacturing process of a toilet is no easy task. It’s a multi-day process that requires a lot of attention to detail. Several days must pass between steps to ensure that the finished product is durable and safe to use.

Again, all manufacturers do things differently. But, here are some of the core steps in the production process.

Molding

The first thing toilet makers must do is create a mold. Commodes come in several shapes, sizes, and designs. The molds allow designers to create unique fixtures to meet anyone’s needs.

After the mold is complete, workers will create negative impressions. In most cases, the manufacturers will take impressions in sections. This helps to make the process much easier moving forward. These negatives impressions are usually called “tools.”

Filling

At this point, workers will fill the molds with the porcelain slurry we went over earlier. The slurry is viscous and free-flowing. This ensures that the raw materials get into every nook and cranny of the mold.

The molds then air dry to solidify a bit. To speed things up, some manufacturers will place the molds in a low-heat drying chamber.

The goal is to remove as much moisture as possible. The exact moisture content of the porcelain depends on the formula. But most have around 20 percent. Reducing that moisture content prepared the components for the next stage of the process.

Glazing

After the sections of the toilet are dry, workers remove them from the mold. They will then take some time to remove any imperfections. This includes removing any overflow sections. Sanding the sections down and assembling the toilet is common, too.

Once that is complete, the glaze is applied. This is where that vitreous china enamel comes into play! The production team applies a thick and even coat of enamel to make sure that the fixture is waterproof.

Firing

Finally, we come to the firing stage! The toilets go into a massive kiln. Temperatures in the kiln are around 1,220 degrees centigrade! That’s nearly 2,400 degrees Fahrenheit!

The firing process removes any remaining moisture. It also hardens the enamel to produce that glossy finish we’re all familiar with!

Some manufacturers will apply a red dye that burns off during firing. This helps to ensure that the toilet baked evenly and thoroughly. Exact times depend on the design of the toilet. But they are usually left in the kiln for upwards of 18 hours.

Here is a video to help you get a good idea of what it takes to manufacture a toilet.

Core Components

Toilets are made using more complex than most people give them credit for! The design of these fixtures is simple. But, manufacturers are constantly looking for ways to improve efficiency.

To give you some more insight into what it takes to produce a well-made toilet, here are the core components every modern-day commode has.

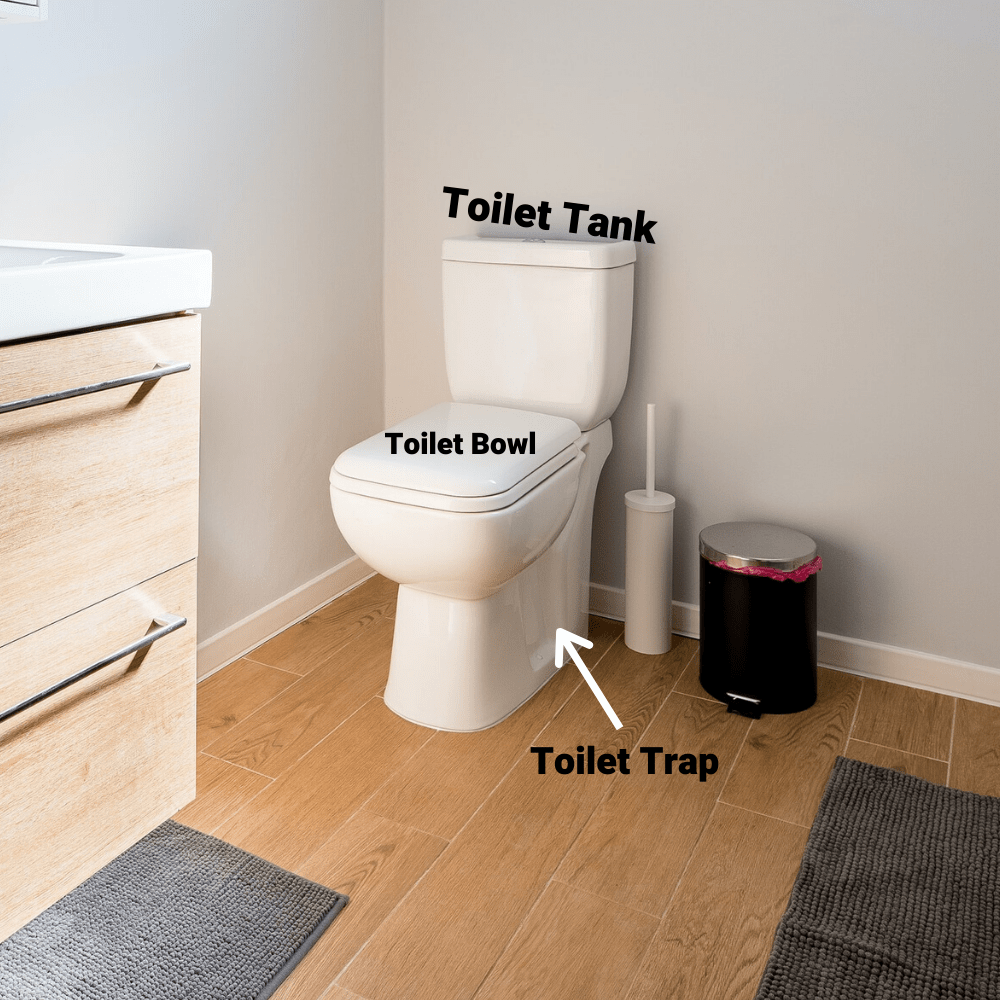

Bowl

The bowl is where all the waste collects before flushing. It looks simple. But bowls have a couple of important features.

Around the rim of the bowl, you’ll find small holes. This is what delivers the water from the tank for flushing. On the bottom of the bowl is the connection to S-trap.

Water Tank

The water tank is the small reservoir behind your commode. Not all toilets have a tank. But most residential models do. It’s the simplest way to deliver waste!

That tank holds onto several gallons of water. Newer models use 1.6 gallons of water at most. Older ones can use upwards of seven gallons! If you’re looking for a water-saving model, check out this option from American Standard.

When you pull the flushing lever, water from the tank surges into the bowl. This helps to trigger the trap below and remove waste.

Trap

Take a look at the side of an unskirted toilet. Notice the defined curve extending from the bowl to the floor? That’s known as the trap.

Toilets can have an S trap or a P trap. Either way, it’s an ingenious design element that creates the vacuum to flush waste away.

The top of the curve contains air. Every time you flush, the water from the tank forces moves over that top curve. This creates a siphoning effect to move waste down the drain!

Flushing Mechanics

Lastly, there are the flushing components. Located inside the tank, these components are responsible for triggering the flush. Toilet design has come a long way in recent years. Thus, there are a few different options available.

You can get toilets with basic lever flushes or advanced push-button mechanisms. Either way, they operate on the same principles. Flushing lifts the flapper valve at the bottom of the tank. This sends water from the tank into the bowl for flushing.

The tank also contains a ballcock. It controls the water valve to refill the tank and prepare for the next flush.

Conclusion

Toilet design is continuing to evolve. But, the core mechanics and manufacturing processes remain the same. Check out this toilet from American Standard if you’re looking for a well-made classic commode.

Still have lingering questions about how toilets are made? Leave your questions in the comments below!

Creating a toilet reliable toilet is a lengthy process. It requires many steps and involves a specifically formulated collection of raw materials to make. There’s a lot of work that goes into your most frequently used fixture. But, it’s well worth it for the convenience!